Stretch Wrappers: Unleashing the Efficiency of Packaging

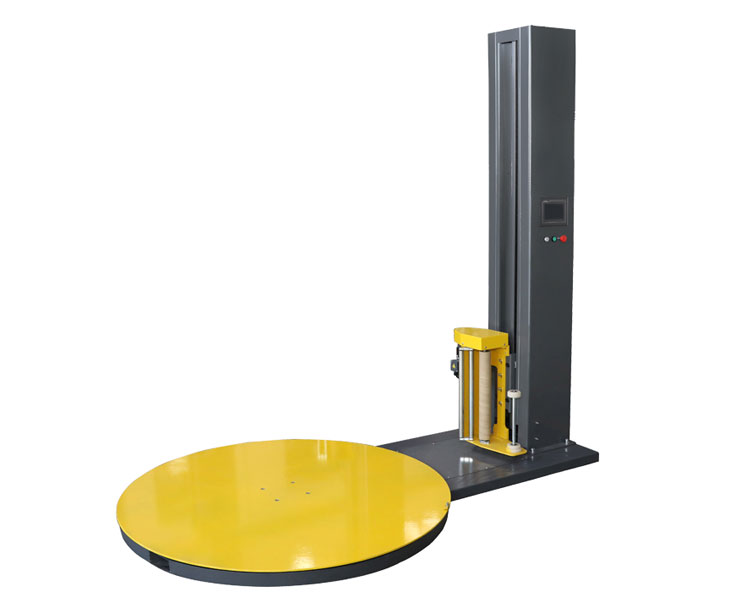

Stretch Wrap Machine

In the realm of modern packaging solutions, the pallet wrapping machine, also known as a pallet wrapper or stretch wapper, stands as a true champion. With its ability to securely and tightly encase palletized products with a layer of stretch wrap, this ingenious invention has revolutionized the logistics industry.

Gone are the days of labor-intensive manual wrapping, as the stretch wrap machine takes center stage in transforming the way goods are packaged for transportation and storage. By automating the process, it not only offers increased efficiency but also ensures uniformity and consistency in the wrapping technique.

The versatile nature of the stretch wapper allows it to handle various sizes and shapes of pallets, adapting effortlessly to the requirements of different industries. From fragile goods that need extra protection to heavy loads that require stability, this machine caters to the diverse needs of businesses across the board.

Not only does the pallet wrapper bring speed and convenience to packaging operations, but it also plays a vital role in minimizing product damage during transit. By keeping the goods tightly bound together, it prevents shifting, toppling, and other potential hazards that could arise during handling and transportation.

In essence, the stretch wrapper is a game-changer in the packaging world, offering an unrivaled combination of efficiency, reliability, and cost-effectiveness. As businesses strive for streamlined operations and enhanced customer satisfaction, embracing this technology becomes an essential step towards achieving these goals.

So, let us delve deeper into the remarkable features and benefits of the stretch wrapper, uncovering how it continues to unleash the true potential of packaging efficiency.

Benefits of Using Stretch Wrappers

Stretch wrappers provide numerous benefits when it comes to packaging efficiency. From streamlining operations to enhancing product protection, these machines offer significant advantages for businesses in various industries. Here are three key benefits of using stretch wrappers:

Improved load stability: Using a pallet wrapping machine such as a stretch wrapper ensures that products on a pallet are securely wrapped and tightly bound together. The stretch wrap machine applies consistent tension to the wrapping material, creating a tight seal that prevents shifting during transportation or storage. This stability minimizes the risk of damaged goods, ensuring that products arrive at their destination intact and ready for use.

Time and labor savings: By automating the wrapping process, pallet wrappers significantly reduce the time and effort required for packaging. With a pallet wrapper, workers can quickly secure multiple pallets without the need for manual intervention. This saves valuable labor hours, allowing employees to focus on other essential tasks. Moreover, the consistent and uniform wrapping achieved by stretch wrappers eliminates the need for manual adjustments, boosting overall productivity.

Increased cost-efficiency: Stretch wrappers offer cost savings in multiple ways. Firstly, they optimize material usage by stretching the wrapping film, reducing the amount required for each pallet. This leads to lower material costs over time. Additionally, the enhanced load stability provided by stretch wrappers reduces the likelihood of product damage during transit. This reduces the need for costly returns or replacements, ultimately saving businesses money. Moreover, the time and labor savings achieved through automated wrapping contribute to overall cost-efficiency in packaging operations.

Types of Stretch Wrappers

One of the most vital components in the world of packaging is the stretch wrapper. These ingenious machines are designed to streamline the packaging process, ensuring that goods are securely wrapped and ready for shipment. There are several types of stretch wrappers available today, each with its unique features and benefits.

Firstly, we have the pallet wrapping machine, which is specifically designed to wrap palletized loads. This type of stretch wrapper typically comes equipped with a turntable that rotates the pallet as the stretch film is applied. Pallet wrapping machines are highly efficient and can handle a wide range of load sizes and weights. They are commonly used in warehouse and distribution centers where large volumes of goods need to be wrapped quickly.

Another common type of stretch wrapper is the pallet wrapper with a rotary arm. Unlike the previous type, this machine immobilizes the pallet while the rotary arm moves around it to apply the stretch film. This allows for a more continuous wrapping process as the arm can rotate without the need for the pallet to turn. Pallet wrappers with rotary arms are often used for fragile or unstable loads that may be susceptible to movement.

Lastly, we have the stretch wrap machine, which is a versatile option that can handle various packaging needs. These machines come in different configurations, such as semi-automatic or fully automatic, and can be customized to suit specific requirements. Stretch wrap machines are commonly used in industries where products vary in size and shape, as they offer flexibility and adaptability to different packaging scenarios.

In conclusion, the world of stretch wrappers offers a diverse range of options to meet different packaging needs. Whether you require a pallet wrapping machine, a pallet wrapper with a rotary arm, or a stretch wrap machine, these efficient devices pave the way for effective and secure packaging processes.

Choosing the Right Stretch Wrapper

When it comes to selecting the perfect stretch wrapper for your packaging needs, there are a few factors that you should consider. These factors will help ensure that you choose a pallet wrapping machine that optimizes efficiency and productivity in your packaging operations.

First and foremost, it is important to evaluate the size and weight of the loads that will be wrapped. Different stretch wrappers have varying weight capacities and size limitations, so it is essential to choose a pallet wrapper that can accommodate your specific requirements. By selecting a stretch wrap machine that aligns with the dimensions and weight of your loads, you can ensure safe and secure packaging.

Secondly, it is crucial to consider the level of automation that would be suitable for your packaging process. Some stretch wrappers offer manual operation, which allows for more control and flexibility, while others provide fully automated functionality, streamlining the packaging process. Assessing your workload and desired workflow will help determine whether a manual or automated stretch wrapper is the best fit.

Finally, evaluating the available stretch wrapping methods is important in making the right choice. Stretch wrappers offer different wrapping patterns, including the popular spiral method and the less common cross-pattern method. Understanding the advantages and disadvantages of each method, and how it aligns with your packaging needs, will help you select the most suitable stretch wrapper.

By carefully considering the size and weight of your loads, the level of automation required, and the available wrapping methods, you can choose a stretch wrapper that effectively unleashes the efficiency of your packaging operations. Remember, selecting the right pallet wrapper is crucial in ensuring streamlined and optimized packaging processes.